About Us

- Home

- About Us

About Qixiang

Who We Are

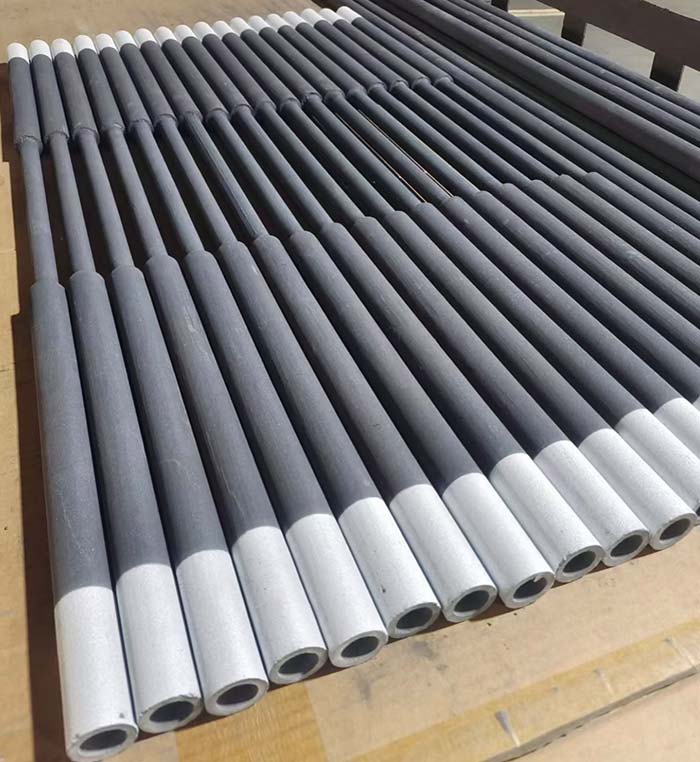

Henan Qixiang New Materials is a professional manufacturer dedicated to silicon carbide heating elements. We focus on high-temperature electric heating solutions for industrial furnaces and laboratory equipment, serving customers across multiple high-heat application industries.

Our Focus

Built Around High-Temperature Heating

We concentrate on the development and production of silicon carbide heating elements in multiple structures and specifications. Our product range covers standard rod types, high-temperature models, and special-shaped elements for different furnace designs and installation needs.

About Qixiang

Customer First, Long-Term Cooperation

We believe stable products and responsive communication are the foundation of long-term cooperation. Our team supports customers with product guidance, selection advice, and service follow-up to build reliable partnerships.

Technical Guidance

Quality Stability

Reliable Delivery

Responsive Service

Delivery

Reliable Packing and Global Shipping

We provide secure packaging and organized shipment arrangements to ensure products arrive safely and on time. With experience in domestic and international deliveries, we support bulk orders and long-term supply cooperation.

- Protective packaging

- Batch order support

- Export shipping experience

- Stable delivery schedules

Related lmages

Your trusted partner for silicon carbide heating elements

Quality Control

Quality Built into Every Step

Quality control runs through the entire production cycle. From material selection to final testing, every heating element is inspected for dimensional accuracy, resistance stability, and structural integrity to ensure reliable performance in high-temperature operation.

Raw material verification

Process inspection

Electrical testing

Final performance checks

Frequently Asked Questions

Model selection depends on furnace temperature, chamber size, installation structure, voltage conditions, and required power load. We can recommend suitable types and dimensions based on your furnace parameters and working temperature range.

Standard models typically operate up to about 1520°C, while high-performance spiral types can reach around 1650°C. Final allowable temperature also depends on atmosphere, loading conditions, and installation design.

Yes. We support customized length, diameter, structure type, terminal style, and resistance range. Custom production is common for furnace matching and helps ensure better heating efficiency and service life.

Resistance increases gradually with usage, which is normal for silicon carbide elements. Our optimized processes help keep resistance growth controlled and predictable for stable power adjustment and longer service intervals.

They are widely used in ceramic sintering, glass processing, metallurgy, laboratory furnaces, electronic materials, and other high-temperature industrial heating applications requiring stable and uniform heat.

We use controlled raw materials, standardized production processes, and multi-stage inspections. Key parameters such as dimensions and resistance are tested to ensure each batch meets industrial performance requirements.

Invitation to Collaborate

Henan Qixiang New Materials invites collaboration

Adhering to the principle of “customer first, service foremost,” we sincerely invite new and existing customers to inquire. Leave your contact information, and we will provide product solutions and technical support, working together to create efficient heating solutions.